- Table size: 70.8” x 33.25” (1800 x 845mm)

- T-slot number x size x distance: 5 x 22 x 150mm

- Table load capacity: 4,840 lbs (2200kg)

- Spindle nose distance from table surface: 8”-35.4” (200 – 900 mm)

- Spindle centre distance from column: 34.25” (870mm)

- Column distance from table center: 17.7” – 50”

- Positioning accuracy: < 0,02mm, 0.0007”

- Repeatability accuracy: < 0.008mm, 0.0003”

- Number and type of X / Y / Z ways: Box ways 2 / 4 / 2

- X travel: 63” (1600mm)

- Y travel: 31.5” (800mm)

- Z travel: 31.9” (810mm)

- Rapid travel speed max. X / Y / Z axis: 15 / 15 / 12m/min

- Max. feed rate: 10m/min

- Size of ball screws: 1.77” (45 x 10mm)

- Max. speed (belt drive): 10,000RPM

- Max. speed (option.): 6,000 RPM (with 2-peed gearbox)

- Spindle taper size (belt drive): #40

- Spindle taper size (gearbox): #50

- Tooling: DIN/BT 40 or 50

- Taper cleaning: Compressed air

- Drive: Belt or gearbox

- Number of ranges: 1 (gearbox 2)

- Headstock cooling: Oil cooler

SPINDLE MOTOR (NCT):

- Number of ranges: 1 (gearbox 2)

- Drive: Belt or gearbox

- Taper cleaning: Compressed air

- Tooling: DIN/BT 40 or 50

- Spindle taper size (gearbox): #50

- Spindle taper size (belt drive): #40

- Max. speed (option.): 6,000 RPM (with 2-peed gearbox)

- Max. speed (belt drive): 10,000RPM

- Rated Power (standard): 25/35 hp (22 kW)

- Rated Power (gearbox): 30/45 hp (28 kW)

- Torque (belt drive): 182 Nm

- Torque (gearbox): 1st range 840 Nm 2nd range 210 Nm

- Motor Cooling: Liquid

- Magazine type: Umbrella / Arm / Chain

- Number of tool positions: 20 / 24 / 32

- Max. tool length: 11.8” (300 mm)

- Max. tool diameter: 4” 100 (6” – 150) mm

- Max. tool weight: 13.2lbs (6 kg)

- Tool change time (T to T): 6-12 ( opt. 3) sec

- Floor space x height: 14.5’ x 11’ x 11’ (4400 x 3330 x 3310 mm)

- Net machine weight: 30,800 lbs (14000 kg)

- Electrical connection: 3 x 460 VAC

STANDARD ACCESSORIES

- Spindle bearing protection by compressed air

- Leveling pads and bolts

- One color alarm lamp

- Double LED lights

- Coolant system

- Air cooling

- Water gun operated by push button

- Air gun connection

CONTROL AND ELECTRONICS

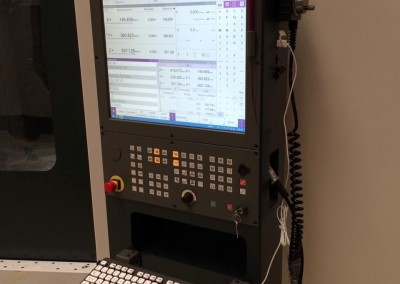

- NCT 201 Smart Touch Controller 19″ touch screen

- EnDat 2.2 absolute measuring system, 0,00005 mm positioning resolution and Nano interpolation

- External swing-aside control panel

- External handwheel

- HEIDENHAIN Indirect measuring system (absolute)

OPTIONS

- Fully enclosed splash guard (enclosed at machine top)

- Increased spindle speed

- Increased spindle torque with motor side gearbox

- Increased spindle torque with headstock gearbox

- Increased spindle taper #50

- Drum type magazine, Arm type, ATC

- Chain type magazine, Arm type, ATC

- Preparation of through tool cooling

- Cooling Through Spindle

- High pressure working space washing apparatus

- Oil skimmer

- Coolant filtering with paper filter

- Spiral, chain or scraper type chip conveyor

- CNC rotary / indexing tables, tailstocks and rotating supports

- CNC tilting rotary tables Hand and CNC tilting rotary tables

- Increased, long term accuracy with Heidenhain linear scales

- Workpiece and tool probe preparation

- Workpiece probe (infra)

- Tool probe (cabled, infra)

- Outer working space lights

- Hydraulic / pneumatic actuating system for table

- Mist extractor

- Automatic door movement

- myNCT graphical programming

- CADCAM software

- Spindle and axis motors quadratic acceleration

- HSHP (high speed high precision machining)

- Sending Error message via SMS

- Switch off the machine from technological program

- Three color status lamp

- Partial or full installation of axis 4

- Partial or full installation of axis 5

- Outputs operated by M function

- NCT simulator

- Remote access

- Robot cell junction interface