Please review our product selection and call us with your application need!

BIG BORE® INCH serration

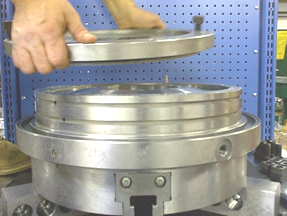

Front-end pneumatic power chucks with extra large through-hole Ø 5.51” – 22” • standard jaw stroke • 3 jaws

Complete machine spindle bore can be used

- Power chuck with built-in pneumatic cylinder. Force transmission via wedge hook.

- Air feed via distributor ring and SMW-profile seals, at stopped spindle.

- A twin non-return valve in the chuck maintains the air pressure during machining.

- Clamping pressure level constantly checked by a safety control system (only for external clamping

- 3 jaw chuck

- 2 elbow unions G 3/8”

- 12 mounting screws (9 for the BB-N 400)

- 1 lifting eye bolt

- 1 set T-nuts with bolts

- 1 set soft top jaws

- without distributor ring bracket

BIG BORE® ES INCH serration

Front-end pneumatic power chucks with extra large through-hole Ø 5.51” – 21” • extended jaw stroke • 3 jaws

Complete machine spindle bore can be used.

For outside clamping only.

- Power chuck with built-in pneumatic cylinder.

- Force transmission via wedge hook with 2 inclinations (for rapid and clamping stroke).

- Air feed via distributor ring and SMW-profile seals, at stopped spindle.

- A twin non-return valve in the chuck maintains the air pressure during machining.

- Clamping pressure level constantly checked by a safety control system (only for external clamping

- Clamping stroke control (no clamping in rapid stroke) is monitored.

- 3 jaw chuck

- 2 elbow unions G 3/8”

- 12 mounting screws (9 for the BB-N ES 400)

- 1 lifting eye bolt

- 1 set T-nuts with bolts

- 1 set soft top jaws without distributor ring bracket

BIG BORE® BBU-AZ-ES INCH serration

Front-end pneumatic power chucks with extra large through-hole Ø 8-5/8” – 14.37” • self centering or compensating clamping • extended jaw stroke • 3 jaws

Tubes can be clamped selfcentering or with radial jaw compensation at bent tubes, using a centering chuck.

No reduction of spindle bore due to selfcontained chuck design.

- Built-in pneumatic cylinder for selfcentering or compensating clamping mode

- Air feed for both functions via air distributor ring at stopped spindle

- Built-in safety valve

- Chuck with mounting bolts

- 1 set of T-nuts with bolts

AXN Automatic indexing chuck

Automatic indexing chucks Ø 8” – 26” • hydraulic clamping and indexing • divisions: 4 x 90° / 8 x 45° / 3 x 120° / 6 x 60° or specials • proofline™ = sealed chucks – low maintenance • 2 jaws

High productivity for machining of work pieces like valve bodies, spiders or fittings (see below) at high position.

AXN: Automatic indexing chuck with hydraulic clamping and indexing

- Rigid holding of the work piece at high revolutions allowing high chip removal rates

- High positioning and repeatability precision

- Reliable indexing system with constant oil lubricated internal mechanism

- Constant and automatic in-process controls for extremely safe machining

- Proofline = fully sealed/low maintenance

- Components supplied on request

- Adapter parts and clamping jaws

SMW CHUCK REPAIR AND REBUILD

Marathon Machine Tools offers air and indexing chuck rebuild services to its customers. A chuck rebuild can be part of a complete machine tool rebuild or an independent service work. Our qualified technicians completely disassemble the chucks and repair or replace worn out parts. Precision grinding services are also offered as part of a total reconditioning.